|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cables & Connectors | >Flexible driver connection for long travel lengths |

Flexible driver connection for long travel lengths

04 April 2025

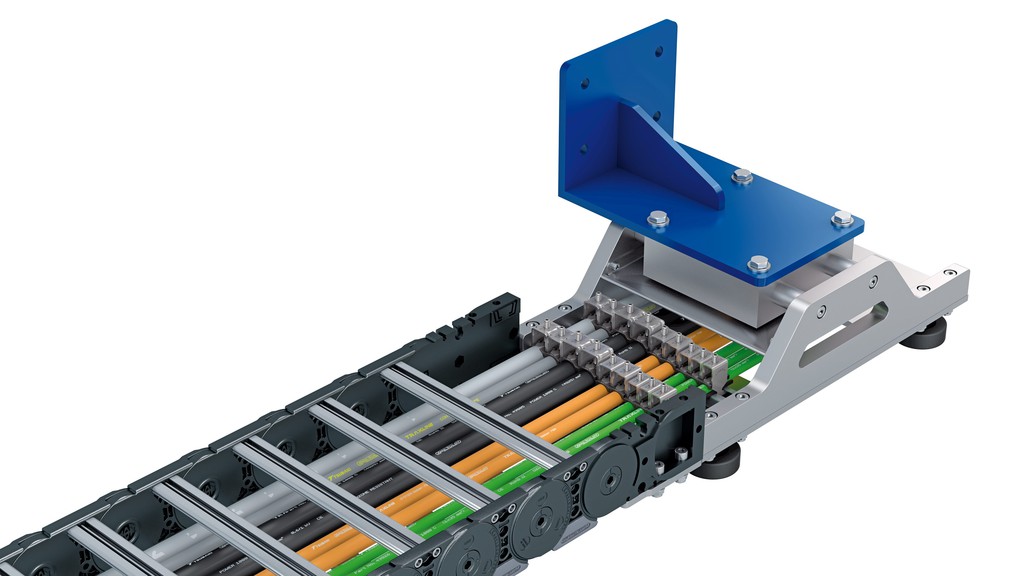

Applications with increased lateral offset – such as industrial systems with particularly long travel lengths – can produce a strong transverse load on drag chains. A flexible driver connection is required to compensate for inaccurately aligned channels or possible wear on the rollers. With the Floating Moving Device, Kabelschlepp Metool offers a safe, robust solution which is also suitable for rough environments.

The Floating Moving Device creates a flexible connection between the drag chain and the driver arm of a system. Areas of application for the driver connection are, for example, crane systems in seawater environments as well as material handling or bulk goods applications.

Peter Sebastian Pütz, head of crane business at Tsubaki Kabelschlepp, explains: “For long travel lengths which are not absolutely straight, the connection has to ensure a relative motion between the connection of drag chain and the system driver to compensate for any inaccuracies and to minimise wear on the drag chain guiding. This also compensates for the concurrent error between system and cable carrier.”

The integrated strain relief ensures reliable cable guiding and a high level of system availability. In addition, a combination with the push and pull force monitoring unit from Kabelschlepp Metool is also possible. The guiding without transverse loads is gentle on the drag chains while also minimising defects, malfunctions and downtime. Simple connection and assembly options also reduce production, maintenance and service costs for the system operator. In connection with the Steel Guide System (TKSG), wear on the roller-guided system can be minimised.

The Floating Moving Device is available in stainless steel or aluminum and can also be painted to customer specifications. It is suitable for the cable carrier types M0950, M1250, M1300 and TKHD90 from Kabelschlepp Metool. The inner width is available in 1mm sections. The horizontal tolerance compensation is at least +/-30mm.

The standard connection dimensions of the component allow horizontal and vertical connections, including a glide-optimized GO module. The latter ensures that the upper run is placed on the lower run quickly and in a controlled manner. This produces minimal wear and prevents the cable carrier from rising up in the guiding. The station in the thrust end position has a smaller loop and therefore remains correspondingly short and requires little space.

- Close collaboration key to complex cable installation

- Contact inserts added to connector range

- Specialist distributor award

- Universal cable entry system

- 'Multi-pole combination connector for power and signals

- Connectors for harsh environments

- Spring pressure speeds installation

- Connectors: 100% tested

- Cable trails and tags

- Reusable industrial clamp