|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Boilers & burners | >CO control with a single probe |

| Home> | Plant, Process & Control | >Boilers and burners | >CO control with a single probe |

| Home> | Energy Management | >Boilers and burners | >CO control with a single probe |

CO control with a single probe

23 March 2018

CO Control is now possible using a single in-situ flue gas probe and analyser.

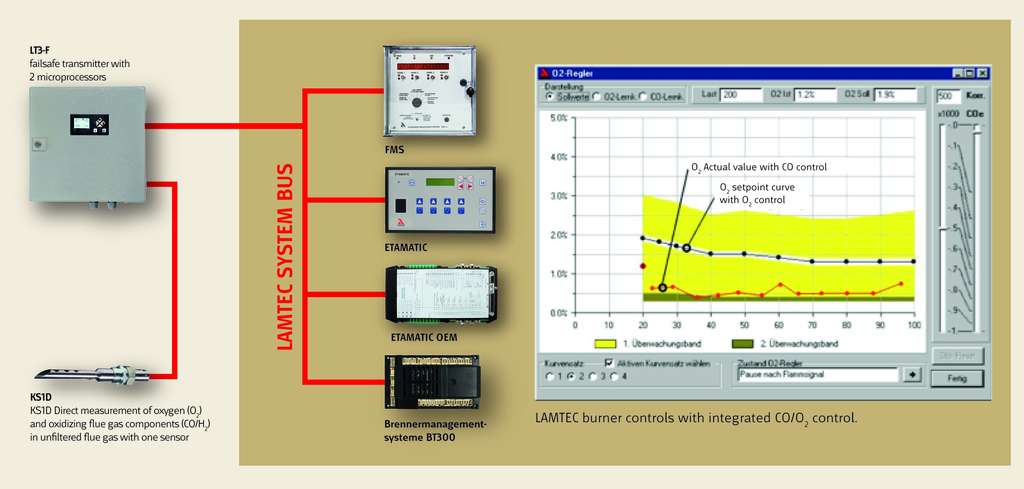

LAMTEC’s LT3-F combustion analyser and KS1D combination 02/COe probe provides a failsafe solution for CO Control when used with a LAMTEC Burner Management Controller. The LT3-F uses two separate processors to cross-check the zirconia probe’s outputs.

The company says CO Control takes a more empirical approach than oxygen trim, enabling combustion systems to get closer to stoichiometric conditions, whilst remaining safe. A self-adapting algorithm optimises the fuel:air ratio over the entire firing range. It ‘learns’ each point on the programmed combustion curve by reducing air to the point where CO is detected and then ‘backing-off’ to a safe setpoint.

Each ’learned’ point has a lifetime of 8h after which it is ‘learned’ again. This ensures that if external conditions have improved then the CO Control will readapt to compensate for this and increase efficiency. It is not uncommon for systems employing CO Control to run at 1% O2. LAMTEC says that, as a rule of thumb, CO Control can generate an additional saving of up to 50% over conventional O2 trim systems.