|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Expert advice |

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >Expert advice |

Expert advice

30 January 2019

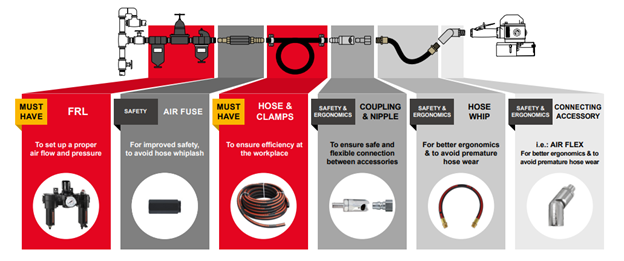

Described by Chicago Pneumatic as a 'must have' for setting up an airline installation in a tough industrial/MRO environment, a Filter Reg Lubricator (FRL) helps ensure regulated clean air is available to the required tooling.

The company says that, for such environments an FRL with a metallic housing is best suited, whereas in smaller less hostile environments a composite version may be used. Often the choice would be FRL units with 2 or 3-stage; both deliver the same functions (Regulation, Filtering, Lubrication). The main differences between them are aesthetics and compactness.

In some cases, where higher dynamic pressure is needed, a 3-stage unit would be recommended. The Air Fuse is a safety item that Chicago Pneumatic recommends be fitted directly after the FRL. This simple, compact unit can be fitted quickly and easily. Its purpose is to shut off the air flow with immediate effect in the event of a poorly fitted hose disconnecting from its coupling or becoming damaged in any way. Without the fuse such a hose (whilst fully charged with compressed air ) would present a serious hose whip hazard within the work area. This would only cease once the airline was manually turned off and that is unlikely to be with immediate effect.

To read more about this, visit: http://www.cp.co.uk and click on 'Expert Corner'.

- Vibration dampened needle scaler

- Following up college support

- Helping UK Museum bring the past to the future!

- Drilling, grinding and bolting solutions

- Cordless options

- Heavy duty grinding in confined space

- Pneumatic Screwdrivers a good choice!

- 2016 Industrial Tools catalogue from Chicago Pneumatic

- A growing team

- Wrench range expanded