|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Lift trucks & ancillaries | >How to reduce total forklift CO2 emissions |

How to reduce total forklift CO2 emissions

12 December 2022

Increasingly, businesses are looking at ways to minimise emissions in order to meet environmental objectives. Lift truck emissions are an important consideration. However, it may not be as straight forward as just switching from ICE (internal combustion engine) to electric forklifts, explains Phil Mean

MINIMISING EMISSIONS across a fleet can be challenging, especially as ICE counterbalance lift trucks still make up a significant percentage of the market in Europe.

Most warehouse equipment is already electric, and many different electric forklifts are already available. Yet businesses often wait for the right time to make the switch, keen to move to electrics when they are sure they can do so and maintain the productivity needed and minimise the Total Cost of Ownership (TCO).

The right choice of lift truck will always depend on the specific application. In some instances, moving to electric trucks to help reduce emissions will be feasible. Many electric trucks can provide ICE-like performance, and additional productivity benefits due to faster acceleration times. Yet other applications may struggle to find a comparable electric model that delivers on factors like ground clearance, manoeuvrability, and robustness in outdoor use.

Infrastructure goes electric

There are also infrastructure considerations when moving from ICE to electric forklifts. Operations using ICE lift trucks may be used to quickly and easily refuel their trucks only every couple of days. With electric trucks, they would need to ensure their site features weatherproof charging and/or battery exchange areas and that they have the equipment to move batteries, chargers, and cables. Additionally, storage for spare batteries is a further consideration.

Applications which may be charging multiple batteries at once will also need to consider the related power consumption. Even when opportunity charging highly efficient lithium-ion batteries, on breaks for example, this can pull high currents.

Developing the infrastructure to support charging may require additional investment, so replacing ICE fleets with electric trucks to reduce direct emissions requires careful analysis of the application and its requirements. Involving your equipment supplier or dealer early on can help with this.

Yet, in some instances the right technology for the application may currently be ICE lift trucks. So where does this leave these businesses when it comes to reducing emissions?

Lift truck power source choice is a balance

Understanding indirect emissions is important. There are three internationally recognised scopes for classifying emissions:

- Scope 1 covers direct emissions from owned or controlled sources

- Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling. This is where “wheel to wheel” emissions are covered

- Scope 3 includes all other indirect emissions that occur in a company’s value chain

Switching from ICE forklifts to those powered by batteries clearly reduces Scope 1 direct emissions, as tailpipe emissions are eliminated. However, this does not always reduce Scope 2 emissions. If the aim is to reduce total emissions, both of these elements should be considered as part of selecting the right fleet and its environmental impact.

If a business has determined that IC lift trucks are still the best match for the application, there is still scope to reduce emissions by addressing the indirect emissions of their lift truck fleet. Not all trucks are equal when it comes to 'well to wheel' emissions.

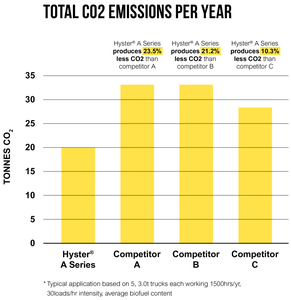

For instance, the new Hyster A Series lift trucks are designed to be highly fuel efficient. In fact, these forklifts are more than 13% more efficient than leading competitors, helping reduce fuel costs by thousands of pounds per year. This performance means that Hyster A Series lift trucks may also produce up to 23.5% less CO2 per year than leading competitors

Phil Mean, product strategy manager for Hyster Europe

For more information:

Tel: 01276 538500

- Li-ion heavyweights

- Lift truck attachments in factory fit programme

- Matching lift trucks to industry demands

- Hyster to give first glimpse of monster electric truck

- 7-9t integrated Li-ion lift trucks

- Materials handling challenges and how to address them

- Hyster A Series - now with 5 year warranty

- Three reasons to choose a Hyster XTLG electric lift truck

- Rider stacker helps manage variable demand

- Celebrating 35 years in Craigavon