|

Edward Lowton

Editor |

|

Composites: Strong growth and opportunities

23 September 2015

FRP composites have made inroads into virtually every end-user industry for a variety of reasons and key advantages. Dr. Sue Halliwell, operations manager at Composites UK, explains more

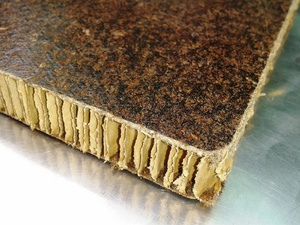

FRP (fibre reinforced polymer) composites are widely used across all end sectors for a huge range of different applications from prosthetic limbs to airplane wings, automotive panels to complete bridge structures, boat hulls to wind turbine blades, to name but a few.

The fibre can be any fibre, but typically we’re talking about carbon, glass or naturally derived such as flax or hemp. Polymers are either thermoset (cross-linked so can’t be re-melted) or thermoplastic (can be re-melted); the choice of which will depend on the application. There has also been work done on self-reinforced polymers such as polypropylene where the fibre and the matrix are the same polymer – this makes recycling easier and there is interest in developing these materials from a range of end-user sectors.

The fact that the material is designed alongside the component means that you can add strength and stiffness at critical points in the design and thus optimise performance. Their light weight, for example, means less energy is required to make an FRP car or airplane move and less cost to run; in construction it could mean reduced road/rail closure times, taller structures, increased bridge spans or improved access; in leisure and sporting activities a stronger lighter product could provide significant benefit. Reduced through-life maintenance is also a key advantage in many applications.

FRP materials are not the answer to every problem, but there are many where they offer a cost and environmentally effective solution. The aim is that they become another option in the designer/engineer toolkit. Designers need to understand the merits and limitations of the use of FRP materials and where they fit into the design spectrum. To replace a part that was in a traditional material (metal, timber etc) and redesign it as FRP doesn’t generally give the best solution. The designer needs to understand the way the material operates not just from a pure material properties point of view but how you can tailor the material to the application.

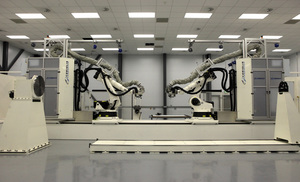

New materials are constantly being developed and existing ones improved so the industry is continually evolving. Alongside this is process development across all scale factors. Recent work through the Composite Leadership Forum (CLF) has developed the UK Composite Strategy 2015 based around manufacturing clusters where there are similarities in the use of production technologies, supply chain configurations, cost models and skills requirements. The strategy (to be published later in 2015) outlines measures to:

• Progress high volume/high performance

• Protect low volume/high performance

• Protect and progress high volume/low cost, semi-structural

• Progress and position mid volume/structural

• Position low volume/large structural

According to market experts, the global industry for composites materials in 2013, across all sectors, had a value of US$68.1bn, with estimated growth of 6.5% CAGR in the next 6 years to about $105.8bm in 2020. There are several major opportunities for the UK in the global arena with considerable growth predicted by Lucintel to 2020:

• Aerospace and defence (predicted growth from $10.6bn to $20bn)

• Transportation (predicted growth from $9.6bn to $15.6bn)

• Construction (predicted growth from 9.6bn to $14.1bn)

• Marine (predicted growth from $1.7bn to $2.5bn)

• Energy (predicted growth from $13bn to $18.2bn)

• Wind energy (predicted growth from $5.6bn to $9.8bn)

FRP Composites is a key growth industry for the UK as documented in the CLF report 2015. The UKTI report published in early 2011 also indicated significant growth for the UK in this sector in volume of material manufactured in the UK and utilised both in the UK and exported abroad. In addition, UK government has invested several million GBP in funding the National Composites Centre and Catapult Centres to ensure the UK industry has the ability to meet this demand. Composites UK is the accredited trade body for the industry and has seen its membership double in the last 2 years, and continue to increase.

- Health and safety seminars

- Support for composites companies

- 2017 composites industry awards

- Three hundred member milestone

- Online health and safety management system

- New report on composites recycling

- Assured practitioner scheme: Up and running

- Dust information seminar

- New renewables showcase event

- Membership milestone