|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Industry 4.0 | >PROFINET and Industry 4.0 |

| Home> | Handbooks | >Manufacturing Matters Ireland | >PROFINET and Industry 4.0 |

PROFINET and Industry 4.0

19 September 2019

PI (PROFIBUS & PROFINET International) is driving the subject of Industry 4.0 and setting out steps for future-proof further development of today's solutions.

The objective is to identify requirements for communication that are important in the Industry 4.0 environment and to standardise them as further development of PI technologies. PI says it is already clear today that PROFINET, with its openness for TCP/IP and its standard Ethernet based technology, has a future-proof architecture that forms a basic prerequisite for Industry 4.0.

Main work is done in PI working group for individual topics. The requirements are closely harmonised with the users and the senior experts in the various companies. The combination of requirements and technical possibilities has resulted in the main areas of focus of TSN, IPv6, Semantics, Security and OPC UA.

PROFINET & OPC UA

Today’s machines and devices generate massive amounts of data. Using an Industrial Ethernet system like PROFINET, this data is accessible for the PLC or DCS. But with Industry 4.0, there is the need to publish this data to IT systems like MES, Asset- or Condition Management applications as well. Today this requires a lot of configuration effort, manual steps like the handling of long Excel charts and the like to make this data available. Since there is no standardised data semantics specified, often the data is not usable in an economically meaningful way.

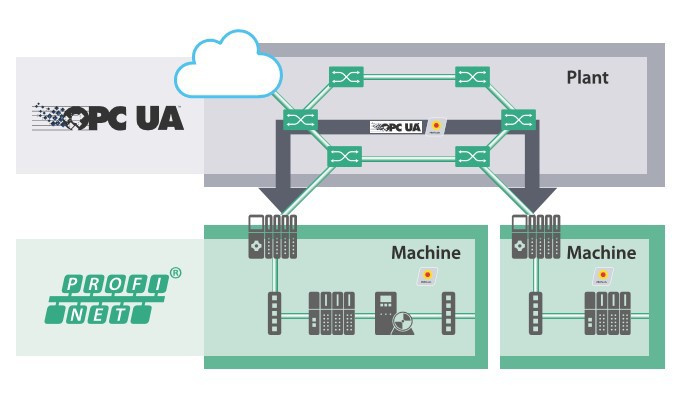

For this reason, PI supports OPC UA as a complementing service in PROFINET networks. OPC UA is an object and service oriented architecture, which features a standardised structure for the transport of data. It actually supports a machine-readable description of the data packages.

An advantage of PROFINET is its openness for further Ethernet traffic. OPC UA can run in parallel without disturbing the cyclic messages. By combining PROFINET and OPC UA, PI believes you can have the best of both worlds. Deterministic real-time behaviour and semantically structured IT connectivity. Doing so, new business models can be applied and Industry 4.0 use cases like Predictive Maintenance can be brought to live. This is why PI is fostering a partnership with OPC Foundation for many years now.

- PROFIenergy explained at June conference

- Certified Profibus and Profinet training

- PROFIBUS systems course

- omlox: The Locating Standard of the Future

- PROFIBUS, PROFINET and IO-Link: Seminar

- Ethernet APL enables PROFINET in the Field of Process Plants

- VentilatorChallengeUK's first ventilator given official go-ahead

- PROFINET, PROFIBUS and IO-Link: Free training event

- Practical aspects of PROFINET, PROFIBUS and IO-Link

- Certified online Profibus and Profinet training