|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >Boilers & burners | >Vertical tubeless steam boiler |

| Home> | Plant, Process & Control | >Boilers and burners | >Vertical tubeless steam boiler |

| Home> | Energy Management | >Boilers and burners | >Vertical tubeless steam boiler |

Vertical tubeless steam boiler

20 November 2018

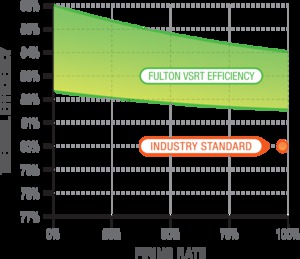

Fulton's new VSRT vertical steam boiler is said to provide high operating efficiencies (84% gross thermal efficiency), resulting in lower operating costs.

These operating efficiencies are achieved due to the VSRT’s long heat transfer path and double-wall annular spiral rib heat exchanger that are fully-water-backed. This means that heat is transferred in two directions to double the heat transfer area in a fixed volume. The fully-water-backed design of the VSRT also allows low jacket losses which, combined with low flue gas temperatures, provides the highest thermal efficiencies.

Its combustion technology – featuring a Fulton-designed modulating burner and furnace that have been designed as a single component and fully-matched with the VSRT in mind – has helped Fulton to achieve ultra-low NOx emissions of less than 20ppm and up to 10:1 turndown capability. Additionally, when correctly sized for applications, Fulton says the high turndown of the VSRT will result in savings above and beyond those gained from the stated efficiencies.

Steam output & quality

At 1306 litres, Fulton says the water volume of the VSRT-60 is almost 120% greater than equivalent 60HP vertical tubeless steam boilers yet, despite the increased volume, the VSRT still has a start-up time of 10-15 minutes and its installed footprint is up to 25% smaller. At 8 bar, the VSRT achieves a 99.75% steam quality.

Durability & warranty

Thanks to its down-firing burner alignment – that eliminates flame impingement on the pressure vessel – and the VSRT’s patented spiral-rib heat exchanger design that virtually eliminates thermal stress, Fulton has created a long-lasting boiler that not only improves boiler efficiency, but one that the company believes will beat the competition in every category of durability. All VSRT models come with the assurance of a 10-year warranty on the pressure vessel.

Maintenance

With features including a tubeless design, no internal refractory and an advanced air filtration system as standard, the VSRT is easy to maintain. For applications where contaminated air can reduce boiler uptime, the VSRT’s standard-fit cyclonic air filter effectively separates debris and damaging particles from the combustion air and, because it won’t clog over time, eliminates the need for replacement filters.

Maintenance is further improved thanks to the VSRT’s industrial control platform and easy access to the pressure vessel.

In summary

All the advanced, energy-saving and environmentally-beneficial features mentioned above are standard across the VSRT range, which is currently available with outputs from 160 to 960kg/h. Fulton is also developing a much larger VSRT-250 model – planned for early 2019 – with a steam output of about 4000kg/h, similar to that offered by manufacturers of horizontal steam boilers.

- Radical change to boiler design

- Fulton strengthens aftercare department

- Brewer steams ahead

- Training course achieves CPD certification

- Thermal fluid or steam?: Key considerations

- Ensuring best practice and safe operations with electrically powered steam boilers

- Horizontal boilers

- Change to boiler design

- Fulton strengthens aftercare department with new appointments

- Skid-mounted horizontal boiler