|

Edward Lowton

Editor |

|

| Home> | Energy Management | >HVAC | >Latest fan coil |

| Home> | Premises management/maintenance | >HVAC | >Latest fan coil |

Latest fan coil

02 August 2013

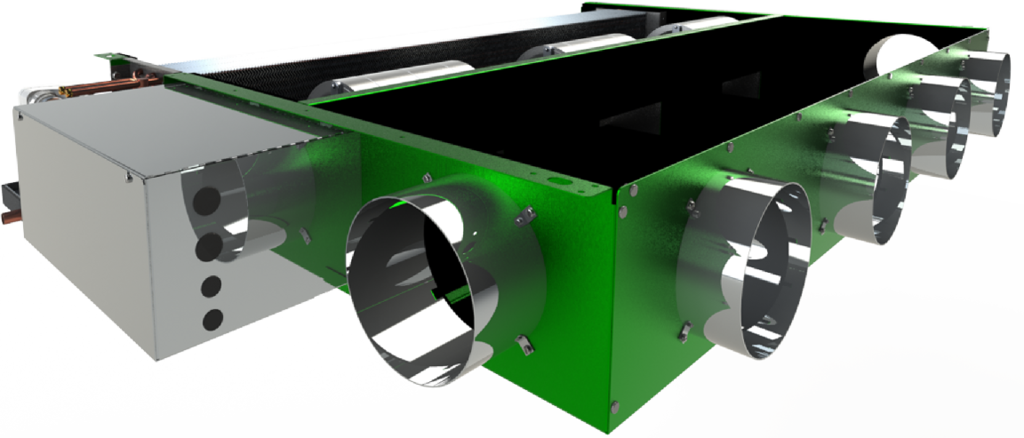

Ability Projects has launched a 190mm deep Matrix self-balancing fan coil, expanding the current Matrix series of 270 and 235mm deep units.

The units use multiple internal rotor fan and motor sets whereby every fan is directly coupled to its own motor, making every fan/motor assembly an independent entity and enabling it to be individually speed controlled.

A key feature is the compartmentalisation of the discharge plenum, such that each fan and motor assembly supplies air into a single sub chamber. Since each sub chamber has only one spigot connection, which ideally serves only one grille, air from each fan is delivered solely to its relevant grille. The air volume to each duct and the balance between ducts is achieved by controlling the fan speeds alone. Matrix systems therefore, do not require volume control dampers.

Ability’s ‘Self Balancing’ EC/DC fans provide a Matrix solution in which each of the fans ‘self adjusts’ its own speed to deliver the air volume that has been pre-defined into the control strategy by Ability for the specific project in question. The design air volume for every grille on every Matrix is factory uploaded into each controller/ strategy as part of the standard manufacturing ‘end of line’ procedures. The Ability control strategy converts this volume requirement (litres/sec) into a control signal voltage (Volts), which in operation, is fed to each of the individual fans in each Matrix unit.

The inevitable differences in static pressure between the individual ducts on a single Matrix unit are compensated for by a continuously running strategy routine. The strategy stores a database of the relationships between motor speed, motor current draw and the speed signal voltage. It evaluates these against the values it senses in real time and is therefore able to make any compensatory speed adjustments necessary, also in real time. Even after hand-over, this self-monitoring and self-adjustment continues to operate such that any static pressure changes, perhaps introduced during ‘fit-out’, will be corrected automatically.

Actual air volume adjustments that may also be required for any one of a number of reasons can also be implemented remotely through the Matrix software, the Matrix ‘Hand Held Tool’ or the BMS. Air volume changes or any other change made through the Matrix software can be applied simultaneously to a single Matrix, a group of Matrix units or a whole project.

- Five green stars

- Fan coil units

- Third generation of software for fan coil units

- Fan coil update

- Fan coil units for landmark building

- Fan coil upgrades: Benefits of modern motors

- Fan coils scoop BREEAM award

- University challenge

- Fan coil units cut waterside commissioning costs by 80%

- Fan coil air conditioning